Our Products

Reach out to us for expert advice and personalized solutions

Need help? Talk to an expert

+91-9313323539Brochure

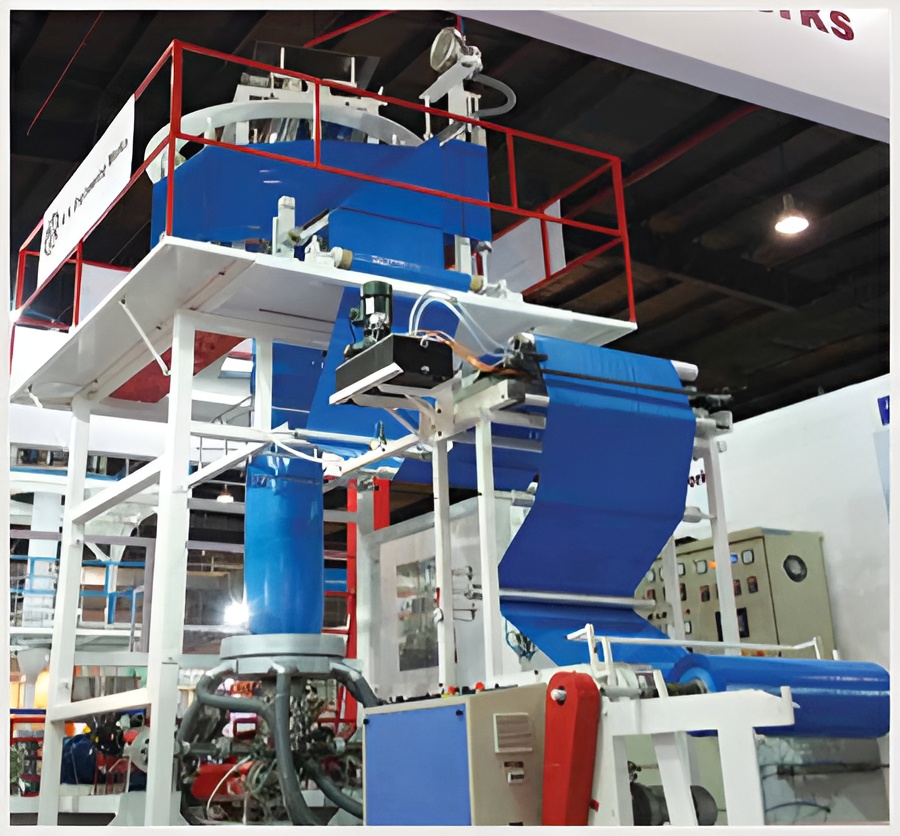

R. K. Engineering Works is a trusted manufacturer and supplier of Multi Layer Blown Film Plants, designed to deliver high performance, superior film quality, and long-lasting durability. Our product range includes Two Layer Blown Film Plants, Multi Layer Film Extrusion Plants, and Multi Layer Blown Film Machines, catering to the diverse needs of packaging and plastic film industries.

Our Multi Layer Blown Film Plants are engineered using advanced technology and precision components to ensure consistent output, uniform film thickness, and excellent mechanical properties. These machines are suitable for producing multilayer films used in various packaging applications such as food products, industrial goods, agricultural films, and more.

Equipped with energy-efficient extruders, automatic temperature control, and high-speed take-up units, our machines are built to meet the latest market demands while ensuring low maintenance and long operational life.

Our Two Layer (A+B) and Three Layer (A+B+A / A+B+C) Blown Film Plants are customizable and fully automated, offering efficient performance with low maintenance requirements. These plants are ideal for producing multilayer films with different material combinations, ensuring better barrier properties, durability, and aesthetic appeal.

Two Layer & Three Layer Film Plant

| Specification | Details |

|---|---|

| Model Type | Two Layer (A+B), Three Layer (A+B+A / A+B+C) |

| Material Processed | LDPE / LLDPE / HDPE |

| Film Width | Up to 2000 mm (customizable) |

| Film Thickness Range | 20 to 200 microns |

| Production Capacity | 50–150 kg/hr (depending on model) |

| Screw Diameter | 45 mm to 65 mm (per layer) |

| Screw L/D Ratio | 28:1 or 30:1 |

| Main Motor Power | 15 HP – 40 HP (as per layer configuration) |

| Die Head Type | Spiral / Rotary |

| Cooling System | Air Cooling with Blower and Chiller Unit |

| Winder Type | Surface / Center Winder |

| Power Supply | 415V, 50Hz, 3 Phase |